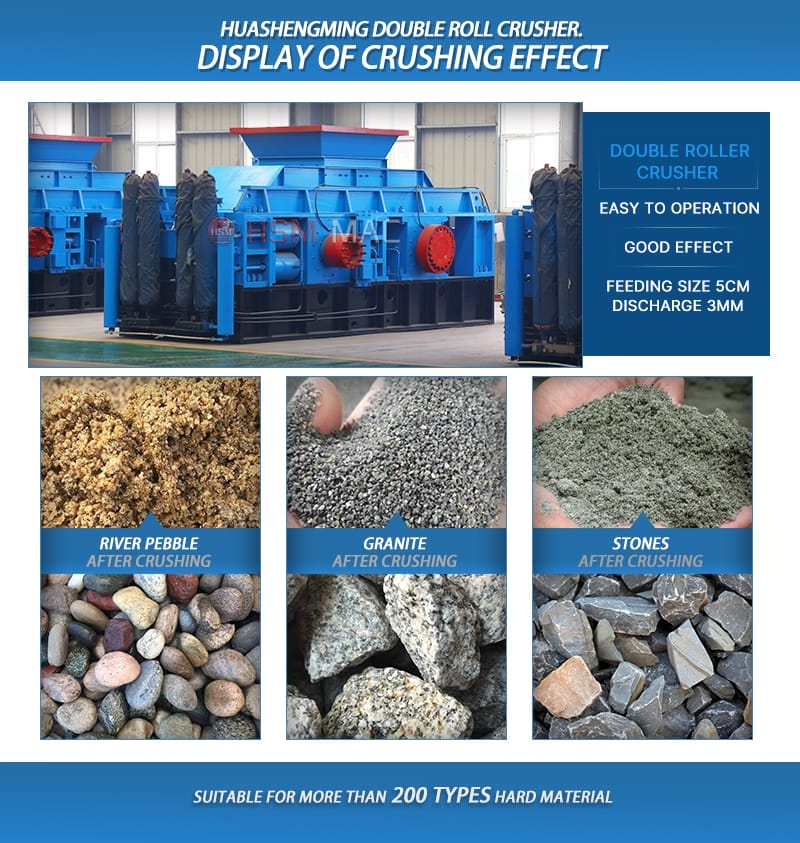

Detailed Working Process:

Feed Intake

- Material enters through the top hopper

Initial Engagement

?- Rolls grip material through surface friction

Compression Phase

?- Material is compressed between rotating surfaces

Size Reduction

?- Fracturing occurs along natural material weaknesses

Product Discharge

?- Sized material exits through adjustable gap

Roller Crusher

This controlled compression process produces uniform, cubical particles with minimal fines generation - perfect for various industrial applications.

Need precise size reduction solutions??Consult with our engineers at Huashengming for customized roll crusher configurations.

]]>

Roller Crusher

More importantly, the quality of the crushed material is superior. The roller crusher excels at producing clean, well-shaped aggregate by effectively separating the hardened cement paste from the natural aggregate.

This results in a stronger, more durable recycled product suitable for high-value applications like road base or drainage layers.

By choosing a roller crusher, you invest in a process that prioritizes both the quality of the end product and the sustainability of the operation.

Produce premium recycled concrete responsibly.?Partner with Huashengming, a leading manufacturer from China’s industrial hub, to implement a clean, efficient?Roller Crusher?system in your recycling flow.

]]>

hydralic roller crusher

Jaw Crusher

1. Working Principle: Extrusion vs Compression-Shear

2. Structural Design: Compact vs Robust

3. Applicable Materials: Medium-Soft vs Hard

4. Product Characteristics: Uniform Particle Size vs Coarse Crushing

5. Production Capacity and Energy Consumption

6. Application Scenarios: Secondary Crushing vs Primary Crushing

Summary: How to Choose?

roller crusher

Its core benefit lies in delivering?controlled size reduction?that directly addresses the challenges of brittle, crystalline lithium minerals.

The crusher excels by producing a narrowly sized, cubic product with a significantly lower percentage of problematic fine particles. This is achieved through its adjustable roll gap, which allows operators to dial in the exact product specification needed.

By minimizing fines, it not only improves the efficiency of downstream processes but also reduces reagent consumption in beneficiation and lowers overall energy use. Its robust, low-wear design ensures reliable operation with less maintenance, making it a cost-effective and reliable?lithium ore crusher?solution for continuous mining operations.

Discover a more efficient path to lithium concentration. Inquire about our Roller Crusher specifications today.

]]>

How Does a Jaw Crusher Work for Granite?

Why Is Jaw Crusher the First Choice for Granite Crushing?

Practical Application Scenarios of Jaw Crusher in Granite Processing

Key Tips for Choosing a Jaw Crusher for Granite Crushing

cone crusher

Impact Crusher

Key Advantages of Impact Crushers:

1.Suitable Crushing Principle:

Utilizes impact and rebound crushing, efficiently processing brittle materials like concrete and bricks while stripping surface mortar to improve sand purity. Cone crushers, designed for hard rock, are prone to clogging with these materials.

2.Ideal Product Shape:

?Produces cubical particles with low flakiness, providing optimal direct feed for?construction waste sand making machines?and enhancing final sand gradation.

3.Cost-Effective Operation:

Features a simpler structure for easier, lower-cost maintenance compared to the complex hydraulic systems of cone crushers.

4.High Impurity Tolerance:

Can handle occasional metal or plastic contaminants without major shutdowns, ensuring better production line uptime.

Ready to optimize your construction waste recycling line??Contact us to discuss how our Impact Crushers can enhance the efficiency of your?construction waste sand making machine?operation.

]]>

box hammer crusher

What Exactly Is a Box Hammer Crusher?

Core Advantages of Box Hammer Crushers

1. High Crushing Ratio & Uniform Product Size

2. Compact Structure & Easy Installation

3. Low Operation & Maintenance Costs

4. Strong Adaptability to Raw Materials

Typical Applications of Box Hammer Crushers

Key Tips for Selecting a Box Hammer Crusher

Final Thoughts

The Current State of the Crushed Stone Market: Challenges Loom Large

Bright Spots Amid the Gloom: Who Is Still Making Money?

Key Factors Determining Profitability: Beyond Market Trends

1. Cost Control: The Lifeline of Profitability

2. Product Differentiation: Escaping Price Wars

3. Policy Compliance: Avoiding Operational Risks

Conclusion: Profitability Is Possible for the Prepared

hydralic roller crusher

Advantage 1: Precise Size Control

-

Adjustable roll gap (1-30mm) for precise calibration.

-

Produces uniform output with an ultra-fines generation rate below 8%.

-

Creates ideal feed material for the?Bricks Sand Making Machine.

Advantage 2: Significant Energy Efficiency

Roller Crusher

-

Reduces specific energy consumption by 30-40% compared to impact crushing.

-

Low-speed, high-torque design is well-suited for brick crushing characteristics.

-

Lowers overall system energy consumption, improving economic returns.

Advantage 3: Broad Material Adaptability

-

Capable of processing brick material with clay content up to 15%.

-

Tolerates construction waste with small amounts of wood or plastic.

-

Easy maintenance leads to low operating costs.

Advantage 4: Superior Environmental Performance

-

Enclosed design reduces dust emissions by over 60%.

-

Noise levels controlled below 85dB.

-

Complies with international environmental standards.

Advantage 5: High Return on Investment (ROI)

-

Typical equipment payback period of 8-14 months.

-

Paired with a?Bricks Sand Making Machine, significantly enhances overall system profitability.

-

Durable construction ensures low maintenance costs.

Roller Crusher

1. Gentle Yet Effective Processing

Our Roller Crusher provides the optimal balance between crushing efficiency and material preservation when processing soil. Unlike high-impact crushers that can pulverize clay particles, the controlled compression method maintains soil structure while achieving the necessary size reduction for your?soil sand making machine.

2. Superior Moisture Management

Designed specifically for soil applications, our Roller Crusher handles materials with 15-30% moisture content without clogging. The counter-rotating rolls create a self-cleaning action that prevents material buildup, ensuring continuous operation in your?soil sand making machine?production line.

3. Energy-Efficient Operation

Compared to impact crushers, our Roller Crusher operates at 35% lower power consumption when processing soil materials. The efficient compression technology reduces energy costs while maintaining high throughput for your complete?soil sand making machine?system.

4. Consistent Particle Size Control

The adjustable roll gap allows precise control over final product specifications. This ensures uniform feed for your downstream?soil sand making machine, optimizing its performance and producing consistently graded manufactured sand that meets construction standards.

5. Low Maintenance & High Durability

With fewer moving parts and specially coated rollers resistant to soil abrasion, our Roller Crusher requires minimal maintenance. The robust design withstands the variable characteristics of different soil types, providing reliable operation in your?soil sand making machine?processing plant.

]]>