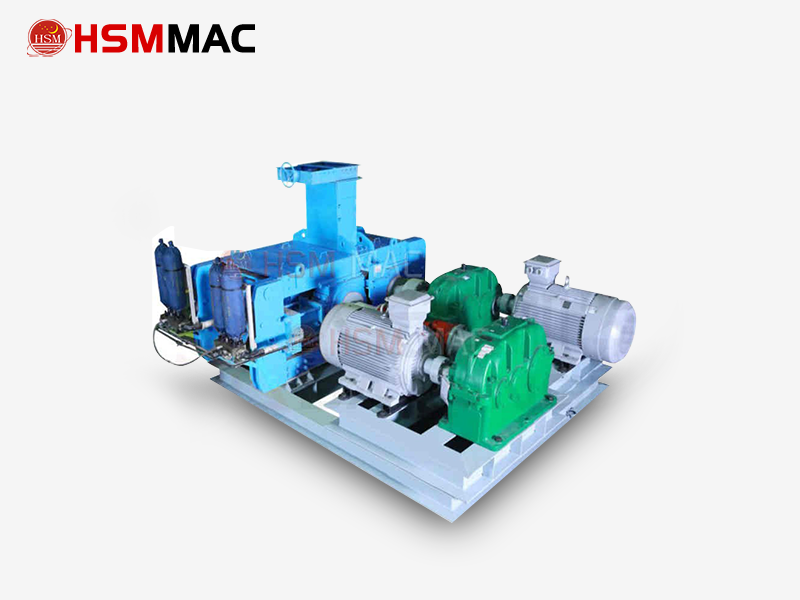

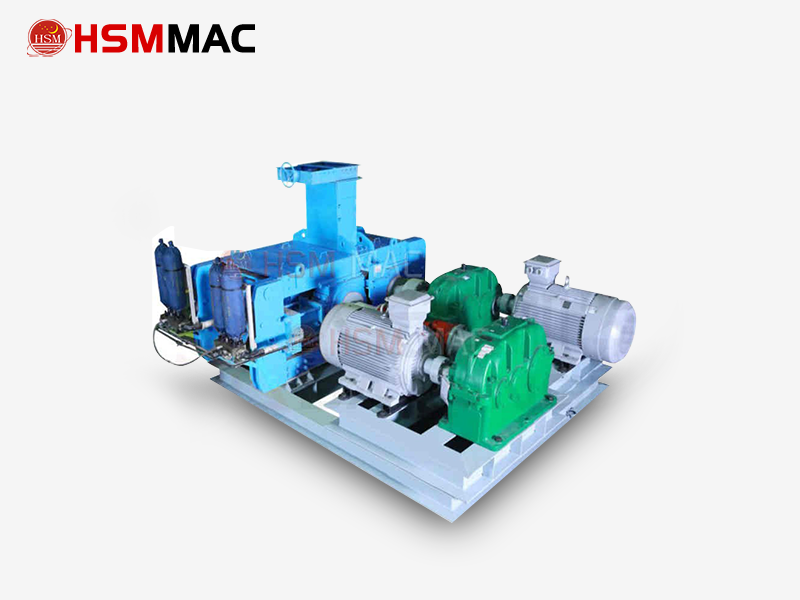

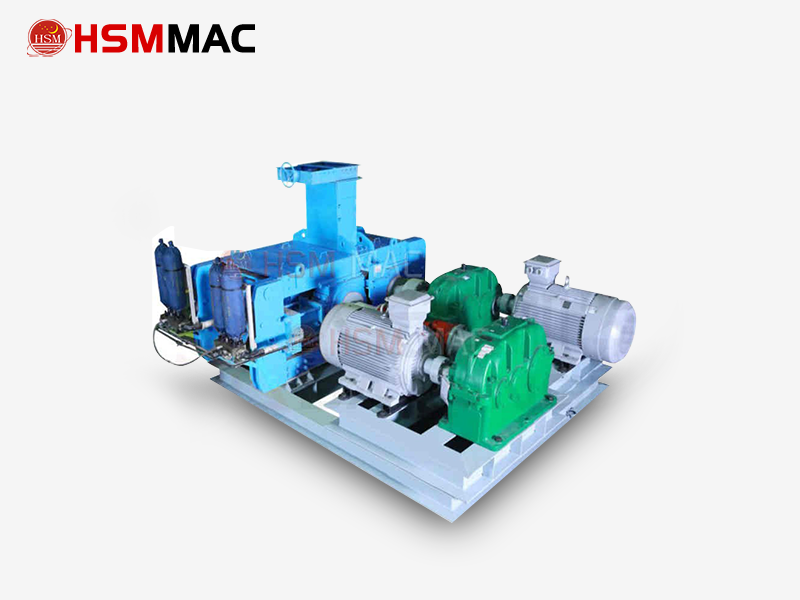

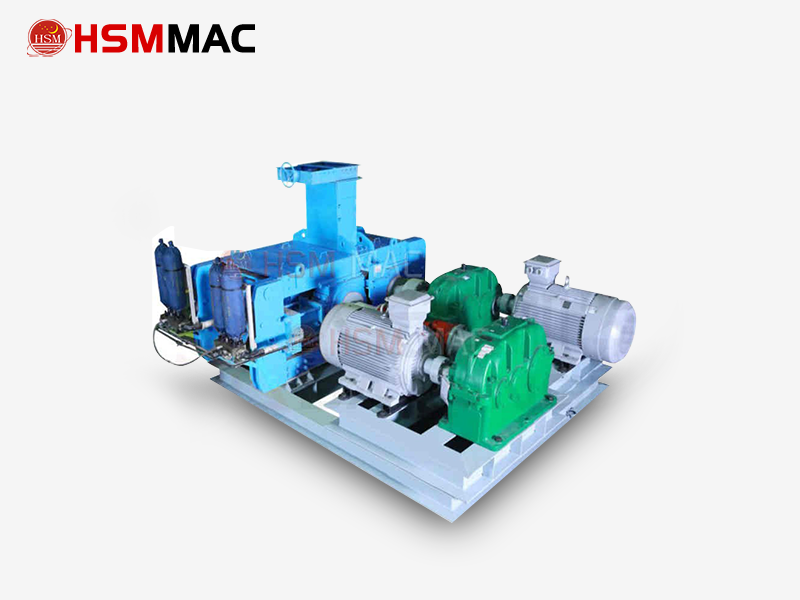

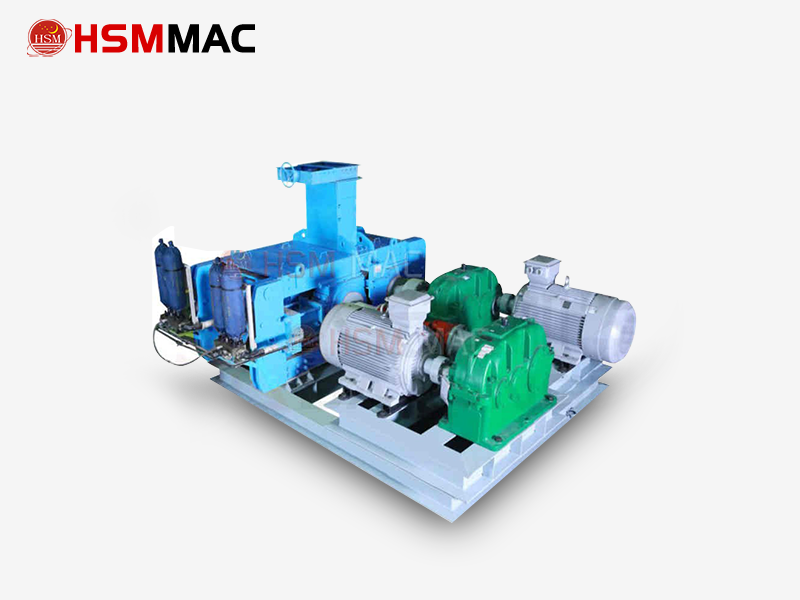

Aluminium dross crushing core equipment

Jaw Crusher + Four Roll Crusher + Eddy Current Sorting + Intelligent Dust Removal System

Crushing equipment selection key points

Coarse crushing equipment

Jaw crusher

Jaw crusher:? Large processing capacity, capable of crushing large steel slag over 300mm, matching with secondary crushing.

Fine crushing equipment

Four Roll Crusher

Technical features: Crushing is achieved through four-roll extrusion, shearing and grinding, and the gap between the upper and lower rolls can be adjusted to control the particle size of the discharged material.

Advantage: Both coarse and fine crushing function, suitable for aluminium dross with more iron impurities (such as aluminium ash dross), easy to separate by magnetic separation after crushing.

Advantages of steel slag crushing programme

Through three-stage crushing + four magnetic separation (suspended magnetic, cylinder magnetic separator, etc.), large slag steel (TFe>80%), particle steel (TFe 60-85%), fine powder (TFe 30-60%) can be recovered. The metal iron content of tailing slag is ≤1%, which meets the standard of building material aggregate (e.g. concrete aggregate needs to be ≤5mm).

Energy saving and environmental protection

Adopt ‘more crushing and less grinding’ process to reduce the energy consumption of grinding (steel slag Bond Index 20-30kW-h/t). Equipped with pulse dust collector (dust concentration ≤20mg/m3) and soundproof cover, in line with environmental emission standards.

]]>

Chrome ore usually takes magma rock or metamorphic rock as the main carrier, with high hardness, it is an important raw material for the industrial production of ferrochrome alloy and chromium metal, due to the strong ferrophilicity of chromium, in nature, chromium and iron are always accompanied by chromite ore is also often called chromite ore.

Chrome Ore Crushing Plant Selection

Primary crushing

Jaw Crusher

Recommended equipment: Jaw Crusher

Characteristics: Jaw crusher is suitable for processing large and high hardness ores, and its heavy body and wear-resistant jaw design can effectively deal with the strong abrasive property of chromite.

Optimisation advice: Prefer a jaw crusher with hydraulic adjustment to dynamically adjust the discharge size and reduce overcrushing.

Intermediate Crushing

Impact crusher

Recommended equipment: Impact crusher

Characteristics: Impact crusher is suitable for brittle ores and achieves high crushing efficiency through impact force.

Scenario: If the ore contains more fissures or needs to reduce dust pollution, the cone crusher is preferred.

Fine Crushing Stage

High pressure roller mill

Recommended equipment: High pressure roller mill

Characteristics: High-pressure roller mill has low energy consumption and is suitable for large-scale fine crushing.

Synergistic optimisation of screening technology

Coarse screening

Choice of equipment: Vibrating screen

Function: Separate large particles and return them to the crusher to reduce ineffective crushing energy consumption. Multi-layer screen design can improve screening efficiency.

Fine screening

Equipment: High frequency vibrating screen or rotary screen.

Function: Ensure that the particle size of the finely crushed ore meets the requirements of the subsequent beneficiation process (e.g. magnetic separation or flotation), and improve the grade of the concentrate.

Chrome ore beneficiation process is the key link to ensure the efficient use of chrome resources and sustainable development, through a reasonable process and equipment configuration, can improve the efficiency of chrome ore beneficiation and product quality, reduce production costs and environmental pollution.

]]>Process Flow Design

Tertiary crushing + Screening process

Rough crushing stage: Jaw crusher (e.g. PE series) is used to deal with large steel slag (≤300mm), and the discharge size is controlled at 150-300mm.

Medium crushing stage: Impact crusher for secondary crushing, discharge size ≤ 50mm.

Fine crushing stage: Roll crusher crushes the material to ≤5mm, realising efficient dissociation of slag and iron.

Screening and Magnetic Separation: Vibrating screen with three levels of screening (coarse, medium and fine).? Combined with permanent magnetic drum and cartridge magnetic separator to recover metallic iron and reduce.? The metal content in the tailings to less than 1%.

Core equipment configuration

Jaw crusher × 2 (coarse crushing) Cone crusher × 1 (medium crushing) Roll crusher × 1 (fine crushing) Vibrating screen × 3 (screening) High-efficiency dust collector × 1 (dust control)

Crushing equipment selection key points

Coarse crushing equipment

Jaw crusher

Jaw crusher:? Large processing capacity, capable of crushing large steel slag over 300mm, matching with secondary crushing.

Impact crusher

Impact crusher: adjustable fineness of discharged material (≤50mm), suitable for aggregate production, but sensitive to iron content.

Fine crushing equipment

Roll crusher

Roll crusher: metal iron recovery rate increased to more than 95%, can achieve efficient dissociation of slag iron, tailings metal iron content ≤ 1%, energy consumption is 30% lower than traditional equipment.

Advantages of steel slag crushing programme

Through three-stage crushing + four magnetic separation (suspended magnetic, cylinder magnetic separator, etc.), large slag steel (TFe>80%), particle steel (TFe 60-85%), fine powder (TFe 30-60%) can be recovered. The metal iron content of tailing slag is ≤1%, which meets the standard of building material aggregate (e.g. concrete aggregate needs to be ≤5mm).

Energy saving and environmental protection

Adopt ‘more crushing and less grinding’ process to reduce the energy consumption of grinding (steel slag Bond Index 20-30kW-h/t). Equipped with pulse dust collector (dust concentration ≤20mg/m3) and soundproof cover, in line with environmental emission standards.

]]>

Chrome ore usually takes magma rock or metamorphic rock as the main carrier, with high hardness, it is an important raw material for the industrial production of ferrochrome alloy and chromium metal, due to the strong ferrophilicity of chromium, in nature, chromium and iron are always accompanied by chromite ore is also often called chromite ore.

Chrome Ore Crushing Plant Selection

Primary crushing

Jaw Crusher

Recommended equipment: Jaw Crusher

Characteristics: Jaw crusher is suitable for processing large and high hardness ores, and its heavy body and wear-resistant jaw design can effectively deal with the strong abrasive property of chromite.

Optimisation advice: Prefer a jaw crusher with hydraulic adjustment to dynamically adjust the discharge size and reduce overcrushing.

Intermediate Crushing

Impact crusher

Recommended equipment: Impact crusher

Characteristics: Impact crusher is suitable for brittle ores and achieves high crushing efficiency through impact force.

Scenario: If the ore contains more fissures or needs to reduce dust pollution, the cone crusher is preferred.

Fine Crushing Stage

High pressure roller mill

Recommended equipment: High pressure roller mill

Characteristics: High-pressure roller mill has low energy consumption and is suitable for large-scale fine crushing.

Synergistic optimisation of screening technology

Coarse screening

Choice of equipment: Vibrating screen

Function: Separate large particles and return them to the crusher to reduce ineffective crushing energy consumption. Multi-layer screen design can improve screening efficiency.

Fine screening

Equipment: High frequency vibrating screen or rotary screen.

Function: Ensure that the particle size of the finely crushed ore meets the requirements of the subsequent beneficiation process (e.g. magnetic separation or flotation), and improve the grade of the concentrate.

Chrome ore beneficiation process is the key link to ensure the efficient use of chrome resources and sustainable development, through a reasonable process and equipment configuration, can improve the efficiency of chrome ore beneficiation and product quality, reduce production costs and environmental pollution.

]]>Tin ore crushing process design

Tin ore crushing equipment are: jaw crusher (coarse crushing) → impact crusher (medium crushing) → roll crusher (fine crushing)

Selection of crushing sections

Two-stage crushing: suitable for most of the tin ore (such as medium hardness, uniform particle size distribution), using a combination of coarse + fine crushing.

Three-stage crushing: for high hardness or oversize ore (e.g. raw ore size >600mm), increase the middle crushing link.

Closed loop: through the vibrating screen (such as circular vibrating screen) to achieve the return of substandard materials to re-crushing, to ensure that the final particle size up to standard.

Crushing Plant Configuration Programme

Rough crushing section:

Jaw crusher

Jaw crusher: recommended models such as PE600×900 (capacity 50-100t/h) or PEW860 European jaw crusher (capacity 250t/h), suitable for ores with compressive strength ≤ 320MPa, with large crushing ratio and simple structure.

Middle/fine crushing section:

Impact crusher

Impact crusher: suitable for medium-hard and soft ores, with shaping function and better particle size.

Roll Crusher

Roll Crusher: High efficiency crushing through high pressure roll extrusion, especially suitable for high hardness ores, can reduce dust generation.

Key Equipment Technical Parameters Control

Particle size control

The target size (usually ≤12mm) is achieved by adjusting the crusher discharge and screening equipment (e.g. 15mm screen). Intelligent sensors are used to monitor the crushing ratio and product size in real time, and dynamically adjust the feeding speed and rotational speed.

Optimisation of wear resistance of crushing equipment

The crushing equipment uses wear-resistant materials such as high chromium alloy and titanium nitride to manufacture wear parts (e.g. jaw plates and liners) to prolong service life. Optimise the structural design of the equipment (e.g. impact crusher cavity type, cone crusher laminated crushing) to reduce the wear area.

]]>Manganese ore? Crushing stage classification equipment selection

Rough crushing stage (particle size >200mm)

Jaw crusher

Recommended equipment: Jaw crusher (e.g. PE series)

Advantages: high crushing ratio (6-8), strong impact resistance, suitable for processing large raw ores. Hydraulically adjustable discharge opening (50-150mm) to adapt to different feed requirements.

Applicable scenario: high hardness manganese ore (such as hard manganese ore) or raw ore with high mud content.

Medium crushing stage (target size 2-50mm)

Cone Crusher

Recommended equipment: Cone Crusher

Advantages: Laminar crushing principle ensures even particle size, automatic overload protection in hydraulic system; processing capacity up to 100-800t/h.

Optimised design: short head type cone crusher is used for pre-treatment before fine crushing, reducing subsequent grinding load.

Fine crushing stage (target size 0.5-1mm)

Hydraulic Double Roller Crusher

Recommended equipment: Hydraulic Double Roller Crusher

Advantage: Fine crushing is achieved by roll extrusion and shearing, with uniform discharge and intelligent hydraulic adjustment system.

Matching Screening and Cleaning Device

Vibrating screening equipment

Function: Closed-circuit screening (e.g. circular vibrating screen) returns substandard particles to the crusher, forming a circular crushing process to ensure that the final particle size is qualified.

Technical parameters: screen hole size decreases step by step (e.g. >5mm after coarse crushing, 0.5-1mm after fine crushing).

Cleaning device

Design Points: Install removable cleaning nozzle on the side wall of the screening device, together with the water tank at the bottom, to reduce the dust pollution and separate the impurities.

Applicable scenario: high humidity ores or manganese ores containing more clay to avoid clogging the equipment.

Process optimisation suggestions

Tertiary Crushing + Closed Circuit Screening Process

Steps: Jaw crusher (coarse crushing) → Cone crusher (medium crushing) → Hydraulic Double Roller Crusher (fine crushing) → Vibratory screening → Unsatisfied particles return to re-crushing.

Advantage: Graduated crushing reduces the pulverisation rate (e.g. controlling the particle size below 10mm ≤10%) and improves the quality of subsequent smelting.

]]>Rough crushing stage

Jaw crusher

Jaw crusher: it is suitable for initial crushing, handling large ores (feed size ≤1200mm). With the advantages of simple structure and large processing capacity.

Hammer crusher

Hammer crusher: for high hardness ores containing more rigid materials, with high crushing efficiency and less dust.

Middle and fine crushing stage

Cone crusher

Cone crusher: for medium to high hardness ores, adopting hydraulic control system and adjustable discharge size.

High-pressure roller mill

High-pressure roller mill: used for ultra-fine crushing or pre-grinding, reducing subsequent grinding energy consumption through laminated crushing (closed circuit process product P80 can be reduced to 1.6mm).

Fine Crushing and Grinding

Vertical agitator mill: used in conjunction with high pressure roller mill to replace the traditional ball mill. Energy saving 14.9%~19.5%, suitable for processing 3~5mm closed circuit products.

Ball mill

Ball mill: If traditional process is adopted, it is recommended to configure hydraulic drive system to reduce energy consumption (e.g. φ5.03m×6.40m ball mill with installed power of 3200~4500kW).

About molybdenum ore crushing equipment selection and production line configuration if you want to know the specific content, you can always leave a message!

]]>Three-stage crushing process:

Zinc ore crushing usually adopts three-stage crushing process, according to the ore hardness (Platts hardness coefficient f=8-12) and particle size requirements, divided into coarse crushing, medium and fine crushing, fine crushing three stages

Coarse crushing stage

Jaw Crusher

Equipment: Jaw Crusher

Function: Crushing raw ore (≤700mm) to ≤200mm.

Advantage: deep cavity optimisation design, large capacity (90-1100t/h), strong wear resistance, suitable for high hardness ores.

Middle and fine crushing stage

Equipment selection: Impact crusher

Function: further crushing to ≤50mm, improve crushing ratio.

Advantage: Suitable for low and medium hardness materials (e.g. limestone), good grain size and low energy consumption.

Fine crushing stage

Roll Crusher

Equipment Selection: Roll Crusher

Function: Crush the ore to ≤12mm (into the grinding size), or with closed-circuit screening to achieve a finer particle size.

Advantage: Hydraulic adjustment of crushing, adjustable mode, suitable for high-precision crushing (output 20-550t/h).

The above is the introduction of zinc ore crushing equipment and production line configuration, you can leave a message at any time if you want to know the related equipment and configuration.

]]>Lithium ore crushing plant programme

Lithium ore crushing usually adopts 2-3 sections crushing process, the specific configuration according to the hardness of the ore, processing capacity and finished product size demand adjustment. The following is a typical programme:

Rough crushing stage

After mining down the raw lithium pyroxene, the size is relatively large, need to go through the jaw crusher for coarse crushing, can be a one-time crushing of large ores to medium size, jaw crusher discharging size is usually in the range of 10-30cm.

Jaw Crusher

Equipment: Jaw Crusher

Function: Crushing large raw ore (≤1200mm) to medium size (10-30cm). Technical Advantage: Deep cavity design increases capacity by 30%, overload protection mechanism enhances durability.

Medium crushing stage

The lithium pyroxene from the jaw crusher is sent to the coarse crushing cone crusher to continue crushing.

Impact Crusher

Equipment: Impact Crusher

Function: Further crushing to ≤50mm, optimising the particle size distribution.

Advantage: It is suitable for fine crushing operation, with uniform granularity of finished products, suitable for the requirement of 10-30mm finished products.

Fine crushing stage

High pressure roller mill

Equipment: High pressure roller mill

Function: Produce 0-15mm fine material to meet the needs of grinding or flotation.

Technical advantage: High-pressure roller mill achieves selective dissociation through laminar crushing, and the closed-circuit system can throw off 35% of the waste material, reducing the subsequent processing cost.

Core equipment:

Jaw Breaker + Impact Crusher + High Pressure Roller Mill

Highlights: IoT monitoring system reduces failure rate by 75%, PM2.5 emission ≤ 10μg/m3.

Auxiliary Equipment and Key Technologies

Screening Equipment

Vibrating screen: classify coarse/medium crushed products to ensure the qualified rate of particle size.

Spiral classifier: cooperate with the grinding process to improve the efficiency of fine powder separation.

Environmental Protection and Intelligent

Intelligent dust removal system: integrated cyclone dust removal + bag filtration, dust emission reaches EU standard.

Hydraulic adjustment device: real-time adjustment of crushing chamber gap, adapt to the change of ore hardness.

Selection considerations

Ore Characteristics: Select the anti-wear material according to the hardness of lithium pyroxene, lithium mica and other minerals (6.5-7 Mohs).

Energy consumption control: give priority to hydraulic drive equipment, the comprehensive energy consumption can be reduced to 4.2kWh/t.

Expandability: reserved interface is compatible with flotation, magnetic separation and other subsequent process equipment.

Copper Ore Characteristics and Crushing Difficulties

Copper ore (e.g. cuprite) is usually of medium hardness (Mohs hardness 3-5), but it may contain impurities such as clay and silica, which can easily lead to adhesion or clogging. Therefore, the crushing equipment needs to have strong adaptability and wear resistance.

Copper ore crushing usually adopts three closed-circuit crushing process, the specific flow is as follows:

Rough crushing stage

Jaw Crusher

Equipment: Jaw Crusher

Function: Processing large raw ore (feed size ≤1500mm), crushing to ≤300mm.

Advantages: simple structure, large capacity, strong adaptability, especially suitable for high wet ore.

Medium and fine crushing stage

Impact crusher

Equipment: Impact crusher

Function: further crush the roughly crushed material to ≤50mm, and form a closed-circuit cycle through vibrating screen.

Advantage: Cone crusher adjusts the discharge opening hydraulically to control the uniform particle size; Impact crusher is suitable for fine crushing and shaping to reduce over-crushing.

Ultra-fine crushing and grinding

High pressure roller mill

Equipment: High pressure roller mill

Function: Grinding the ore after fine crushing to ≤0.5mm, providing suitable particle size for subsequent flotation.

Process optimisation

Copper ore adopts the strategy of ‘more crushing and less grinding’ to reduce the grinding load and energy consumption. Closed-circuit screening design can improve crushing efficiency and avoid over-crushing.

]]>