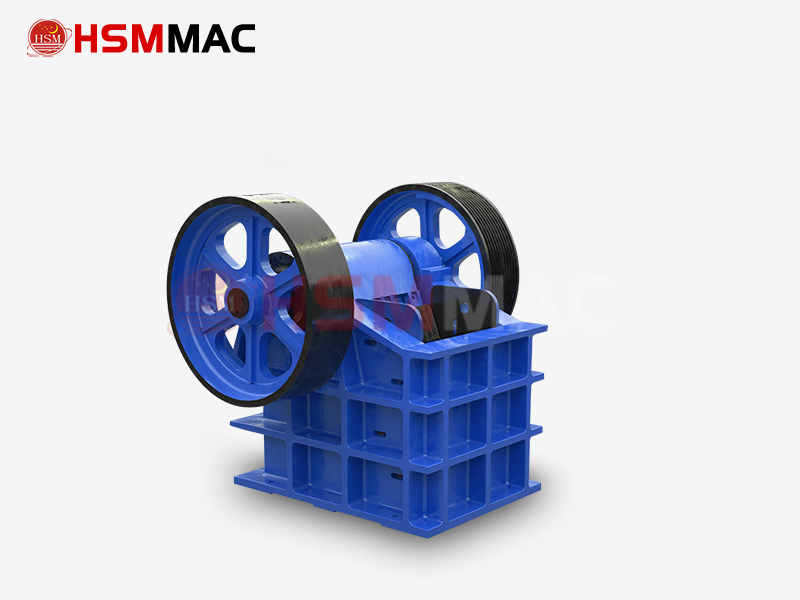

As a vital primary crushing equipment in mining, construction, and aggregate production, the jaw crusher is a reliable workhorse. Below is a condensed guide to its working principle, advantages, applications, innovations, and selection tips.

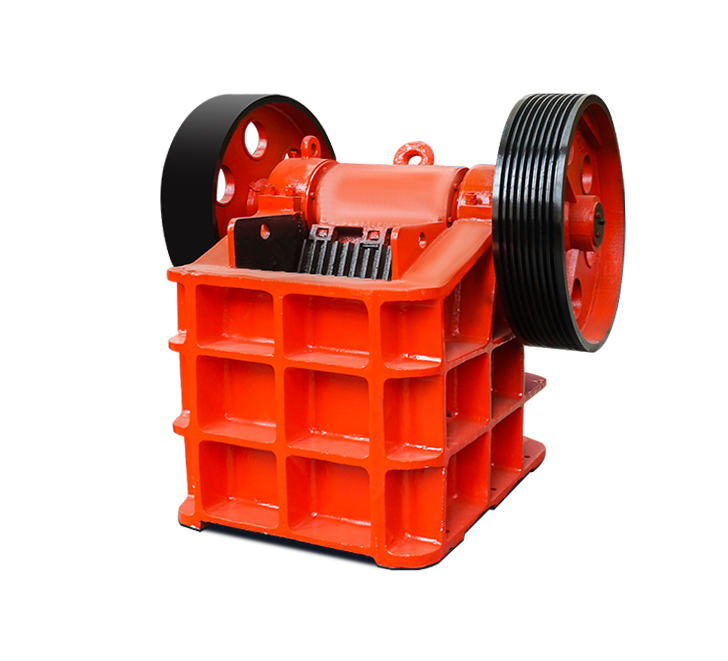

Jaw crusher

1. Definition & Working Principle

A compression crusher for reducing bulk materials, it has two jaws (fixed & movable) driven by an eccentric shaft. Key components include wear-resistant jaw plates, eccentric shaft, flywheel, and discharge adjustment device.

Its working principle is simple: the rotating eccentric shaft makes the movable jaw swing. Material is crushed when jaws close, and falls out when jaws open, enabling continuous operation for large feed sizes.

2. Irreplaceable Advantages

Jaw crushers remain the top choice for primary crushing due to these core advantages:

Reliability & Durability: Simple structure, low failure rate, and high-strength materials for handling hard/abrasive materials.

Wide Feed Range: Handles large raw materials (up to several meters) without pre-crushing.

Cost-Effective: Low maintenance, easy part replacement, and high energy efficiency.

Versatility: Applicable to mining, construction, recycling, and cement industries.

3. Key Applications

Common application scenarios include:

Mining: Primary crushing of metal/non-metallic ores for secondary processing.

Construction: Producing aggregates for concrete, asphalt, and road construction.

Waste Recycling: Crushing construction waste into reusable aggregates.

Cement: Crushing raw materials like limestone for cement production.

4. Latest Technological Innovations

Recent innovations focus on efficiency, energy saving, and intelligence:

Hydraulic Adjustment: Quick, precise discharge sizing and overload protection.

Intelligent Monitoring: IoT-enabled remote monitoring and predictive maintenance.

Energy-Saving Design: 10-20% lower energy consumption via optimized structure.

Wear-Resistant Tech: New materials extend wear part lifespan and reduce downtime.

5. Selection Tips

Key factors for choosing the right jaw crusher:

Material Properties: Hardness, abrasiveness, and moisture content.

Size Requirements: Maximum feed size and desired discharge size.

Production Capacity: Match daily/hourly output needs.

Working Environment: Indoor/outdoor, space, and environmental constraints.

Final Takeaway

With over a century of service, jaw crushers are evolving to be more efficient, intelligent, and eco-friendly. Understanding their core features helps in making informed decisions for your production line.

Have questions about selection or maintenance? Leave a comment below! Share this with industry colleagues and follow us for more crushing equipment insights.