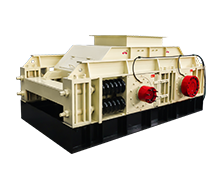

Roller Crusher Roller Maintenance Needs Attention. Maintenance of smooth rolls and toothed rolls in roll crusher requires targeted management based on equipment characteristics, material properties, and operational protocols. Below are critical maintenance considerations and operational recommendations:

Roller Crusher Roller Maintenance

I. Core Daily Maintenance Guidelines

- Lubrication Management

- Smooth Rolls:

Lubricate bearings weekly with specialized grease.

Apply calcium-based grease to chains every 15 days and perform thorough chain cleaning monthly. - Toothed Rolls:

Lubricate bearings monthly and replace grease annually.

Oil chains weekly and clean them monthly. - General Requirements: Ensure lubrication systems remain clean to prevent contamination. Maintain sliding bearing clearance at 0.0001D–0.00015D (where D = journal diameter).

- Smooth Rolls:

- Wear Inspection and Adjustment

- Smooth Rolls:

Clean residual material from roll surfaces after each shift and inspect surface smoothness to avoid pitting or scratches.

Adjust roller gaps every two weeks to ensure parallelism. - Toothed Rolls:

Inspect tooth plate wear every 1–3 months; replace plates if tooth height loss exceeds 30% or fractures occur.

Adjust discharge openings periodically to prevent overly fine output.

- Smooth Rolls:

- Cleaning and Clog Prevention

- Regularly remove adhered material to avoid crushing chamber blockages (especially when processing clay or construction waste).

- Stop feeding 2–3 minutes before shutdown to ensure complete material discharge.

II. Key Component Maintenance Strategies

- Smooth Roll Maintenance

- Roll Surface Replacement: Replace surfaces every 6–12 months (shortened to 3–4 months for high-hardness materials like iron ore).

- Material Optimization: Use high-chromium cast iron or wear-resistant alloy surfaces to extend lifespan beyond 1 year.

- Toothed Roll Maintenance

- Tooth Plate Protection:

Use high-manganese steel or tungsten carbide tooth plates.

Lifespan shortens to 2,000–3,000 hours when processing high-hardness materials (e.g., quartz sand). - Drive System:

Minor overhaul every 12 months (clear blockages, replace safety pins).

Medium overhaul every 36 months (replace gears, adjust belts).

Major overhaul every 72 months.

- Tooth Plate Protection:

III. Safety Operation Protocols

- Startup and Shutdown

- No-load startup: Run the crusher idle for 2–3 minutes to confirm normal operation before feeding. Ensure complete material discharge before shutdown.

- Emergency handling: Never perform cleaning or troubleshooting while the crusher is running; always shut down first.

- Foreign Object Protection

- Install magnetic separators to prevent metal debris from entering the crushing chamber and causing jams or damage.

- Use protective guards when handling large materials to prevent flying debris injuries.

- Load Control

- Feed materials evenly to avoid uneven wear from single-side overload.

- Ensure feed size does not exceed equipment limits (e.g., ≤20 mm for XPZ series crushers).

IV. Special Conditions and Optimization Recommendations

- High-Hardness Material Processing

- Shorten tooth plate inspection intervals to 1 month and use high-chromium alloy materials.

- Increase smooth roll gap adjustment frequency to weekly.

- Automation Upgrades

- Deploy smart monitoring systems to trigger real-time alerts for abnormal conditions (e.g., bearing temperature >65°C, excessive vibration), reducing unplanned downtime.

- Predictive Maintenance

- Use sensor-based monitoring of operational parameters (e.g., temperature, vibration) to predict wear or failures and optimize replacement timing.

V. Common Fault Diagnosis and Solutions

| Fault Symptom | Possible Cause | Solution |

|---|---|---|

| Excessive bearing temperature (>65°C) | Insufficient lubrication or contamination | Clean lubrication system; replace grease. |

| Uneven output particle size | Non-parallel roller gaps or worn tooth plates | Re-adjust gaps or replace tooth plates. |

| Abnormal noise or vibration | Metal debris ingress or loose components | Shut down, remove debris, and tighten bolts. |

Summary

Maintenance of smooth and toothed rolls in double roller crushers must prioritize lubrication, wear inspection, foreign object protection, and operational compliance. Maintenance cycles should be dynamically adjusted based on material hardness and equipment load, with reference to manufacturer guidelines (e.g., Huashengming Heavy Machinery,). Regular operator training and automation upgrades can significantly extend equipment lifespan and enhance safety.