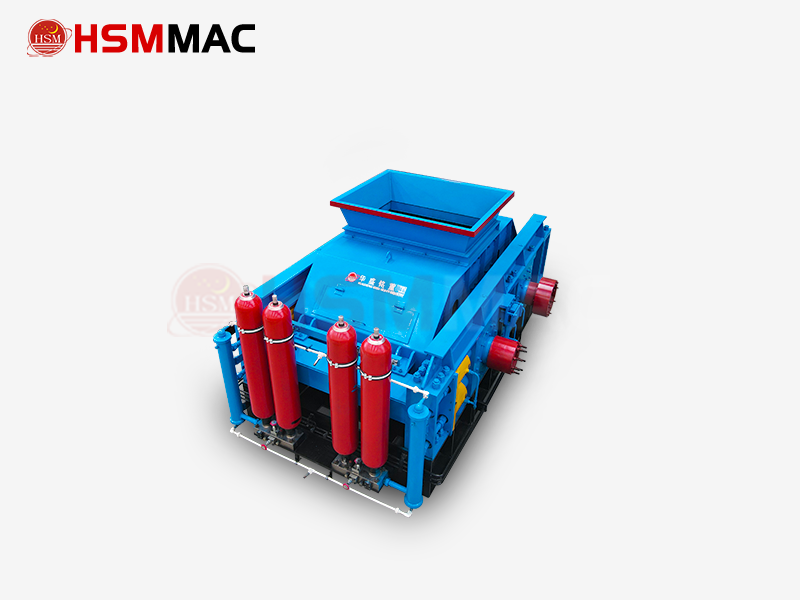

Mobile Crusher Price��?How Much Does A Mobile Crusher Cost?

2025-09-01

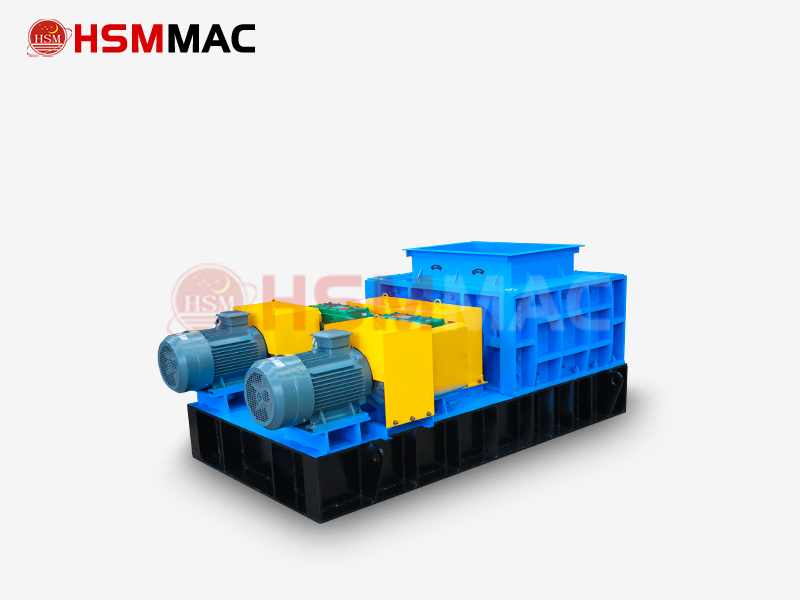

What is the price of mobile crusher? Mobile roller crusher can be selected according to customer demand for coarse crushing, medium crushing, fine crushing and screening equipment and other ancillary equipment, so the price is not fixed, according to different crushing requirements of the Gongyi composed of ‘crushing and then screening’ crushing and screening, can also be composed of ‘screening and then crushing’ crushing and screening process can also be used separately. Crushing and screening can also be used separately. The crushing plant can be combined into two crushing and screening systems according to the actual demand, and can also be combined into three crushing and screening systems: coarse, medium and fine. Applicable materials of mobile crusher The crushing and sand making work of river pebbles, calcite, quartz, glass, marble, pebbles, bentonite, iron ore, lapis lazuli, mountain stone, limestone, weathered sand, pyroxene, granite, basalt and other materials. In the operation of mobile roller crusher, the feeding, crushing and screening equipment coordinates the operation, the stone material firstly enters the crushing part for crushing and processing, and after sand making, it is screened, and the materials with qualified granularity can only enter the sand making machine for sand making and processing,...