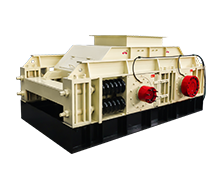

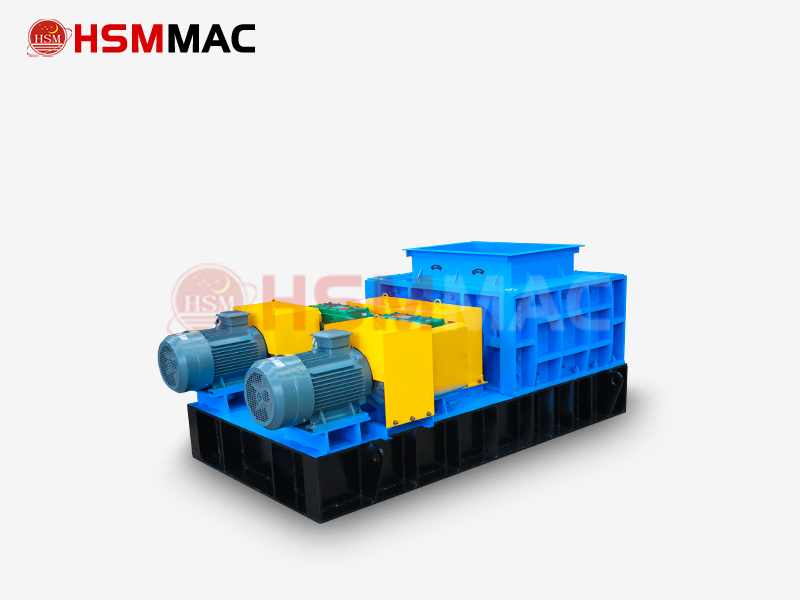

Roller Crusher, The Preferred Equipment In The Crushing Field

2025-04-09

As an efficient and multi-functional crushing equipment, the roller crusher has significant advantages in the fields of mining, building materials, metallurgy, etc., and the roller crusher has become the preferred equipment in the field of modern crushing with its advantages of high efficiency, accuracy, durability and environmental protection. The roller crusher can process a wide range of raw materials, including coal, iron ore, construction waste, steel slag, etc., without the need for pre-screening (e.g., raw coal can be directly crushed), simplifying the process. Compared with other crushing equipment, the roller crusher has low initial investment, less energy consumption and maintenance costs in long-term operation, and significant comprehensive economic benefits. Its technical advantages are not only reflected in production efficiency and cost control, but also meet the current industrial demand for green manufacturing and sustainable development, and are suitable for refined production scenarios in mining, building materials, metallurgy and other industries. 1. High efficiency, energy saving and high production capacity The roller crusher adopts the principle of double-roll extrusion, which quickly crushes materials through high-intensity pressure, especially suitable for medium-hard and brittle materials (such as coal, ore, steel slag, etc.), and its crushing efficiency is 30%-40% higher than that of traditional...