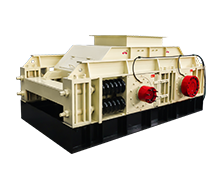

How Does The Roller Crusher Perform In Crushing Materials?

2025-10-28

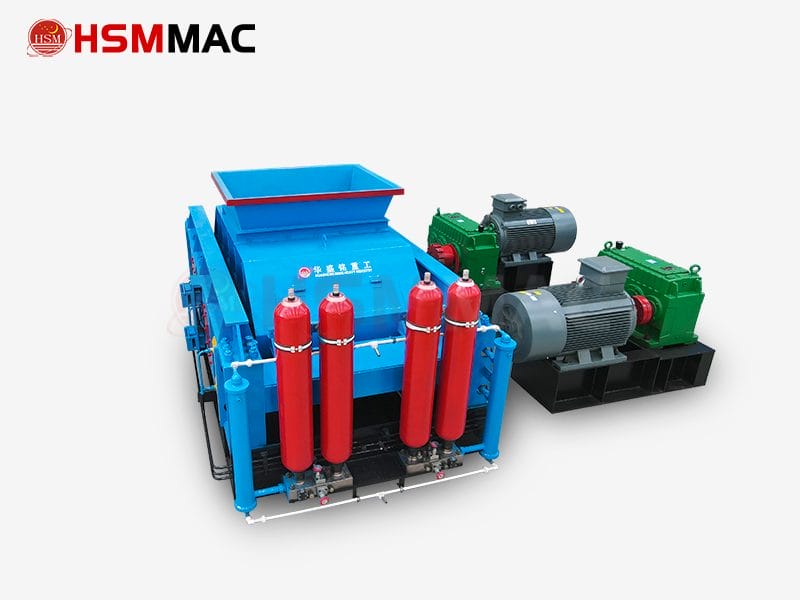

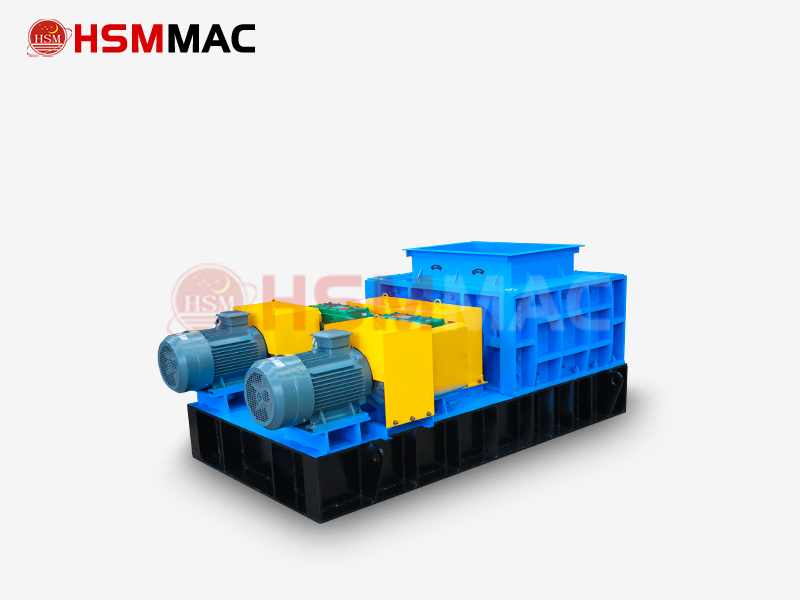

The roller crusher, also known as the double-roll crusher or double-roll sand maker, utilizes two motors to drive two sets of roller shafts to crush and grind materials through compression. This roller crusher is suitable for fine crushing operations with feed sizes under 80mm and finished product sizes ranging from 50 mesh to 20mm. Capable of processing materials with compressive strength ≤160MPa, it serves as an ideal production equipment for construction sand, road-building sand, asphalt concrete, and cement concrete aggregates, suitable for transportation, construction, and other industries. 1.Roller Crusher Feed Size: 25-100mm Production Capacity: 2-400 t/h Suitable Materials River pebbles, calcite, quartzite, marble, cobblestones, bentonite, iron ore, bluestone, quarry rock, slag, limestone, weathered sand, diabase, granite, basalt, etc. Application Scope Suitable for crushing in mining, cement, highway, railway, coal, metallurgy, building materials, and other industries. 2.Working Principle The roller crusher performs crushing operations through roller wheels. Material enters between the rollers through the feed opening and is crushed by compression. A fixed gap exists between the two rollers. Increasing this gap produces larger output particle sizes, while the compression spring forces the gap to narrow, resulting in finer output. By adjusting the gap, the output particle size can be precisely...