types of roller crusher

2025-02-12

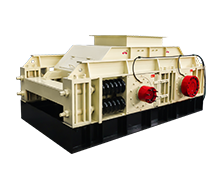

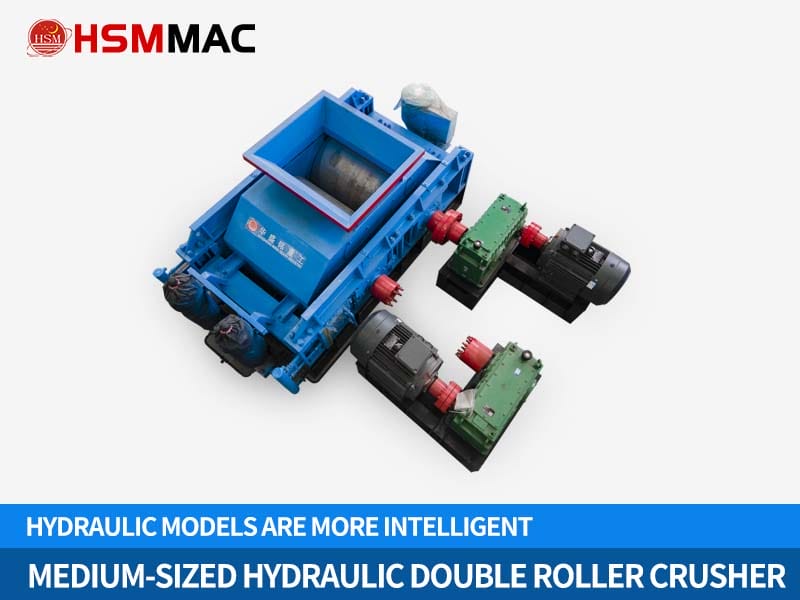

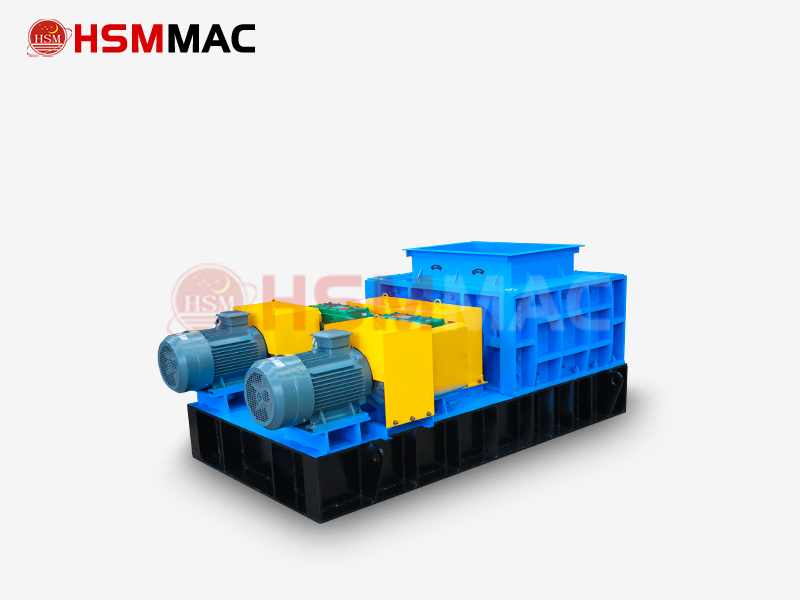

Here are the types of roller crusher, commonly used in mining, building materials, and chemical industries, which are primarily designed for crushing materials of medium hardness: 2. Double-Roller Crusher A double-roller crusher consists of two counter-rotating rollers. The material is crushed by being squeezed and sheared between the rollers. This type is suitable for soft and medium-hard minerals like limestone, clay, iron ore, and coal. The advantages include high throughput, uniform product size, a sturdy design, and low maintenance costs. 3. Triple and Quadruple-Roller Crusher Triple and quadruple-roller crushers have additional rollers to achieve finer material crushing. These crushers are typically used for applications requiring high precision and fine granularity. For example, in a triple-roller crusher, primary crushing is done by the upper single roller, followed by secondary crushing by the lower double rollers. This design allows for larger feed sizes and higher throughput. 4. Toothed-Roller Crusher A toothed-roller crusher has rollers with specially designed tooth patterns on their surface, making it highly effective for handling wet, sticky, and soil-mixed materials. This design prevents the equipment from clogging while maintaining efficient crushing performance, even when dealing with difficult-to-crush materials. Choosing the right types of roller crusher is crucial for achieving...